ball indenter in brinell hardness test|brinell hardness test explained : bulk The indenter used in the Brinell test method is made of a hard metal ball of diameter D = 10; 5; 2.5 or 1 mm. It is applied to the specimen with a test force (to standard from 1 kg to 3000 kg) and held according to the holding time. WEB25 de dez. de 2020 · CRCC是PETROBRAS巴西石油合格供应商资格认证。. CRCC 的英文全称是Certificate of Registry and Cadastral Classification。. 2019年1月21日起,CRCC更改为CRC,全称为Certificado de Registro Cadastral. CRC是根据巴西法令2.745/98,经由巴西石油公司PETROBRAS确定为合格供应商;. CRC将从五 .

{plog:ftitle_list}

新聞專區. 2024年02月26日. 光寶科2023年每股盈餘達NT$6.36元,年增3%,策略轉型建構組織敏捷競爭力,帶動獲利持續成長. 2024年02月07日. 光寶科技元月份全球合併營收NT$ 99億元. 2024年01月09日. 光寶科技十二月份全球合併營收NT$ 123億元. 更多資訊.

The indenter used in the Brinell test method is made of a hard metal ball of diameter D = 10; 5; 2.5 or 1 mm. It is applied to the specimen with a test force (to standard from 1 kg to 3000 kg) and held according to the holding time.

In the standard method of the Brinell Hardness Test, we use 250 to 500 kg of load for soft material and 500 to 3000 kg of load for hard material such as steel and iron. In the standard method of the test, we use a ball indenter of .

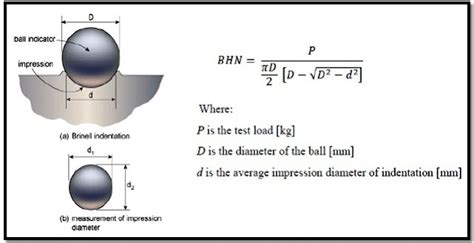

The typical test uses a 10 mm (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29.42 kN; 6,614 lbf) force. For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. The indentation is measured and hardness calculated as: where:The Brinell hardness test uses a hardened steel ball indenter that is pushed into the material under a specified force. The diameter of the indentation left in the surface of the material is .Brinell testing often use a very high test load (3000 kgf) and a 10mm diameter indenter so that the resulting indentation averages out most surface and sub-surface inconsistencies. The Brinell method applies a predetermined test .

Brinell Testing (BHN) Brinell was a Swedish engineer who developed this testing process to determine both hardness and tensile strength. It consists of indenting the surface of the metal .Today, the Brinell test is performed using a Brinell hardness test unit. The machine presses a tungsten carbide ball into the sample, and then optically measures the diameter of the impression. Indenter sizes: 1, 2.5, 5 and 10 mmIndenter sizes: 1, 2.5, 5 and 10 mm ; Loads: From 1 kgf to 3000 kgf ; Maximum hardness: 650 HBW ; A hardness test for larger samples As the Brinell hardness test (HBW) indentation leaves a relatively large impression, the .The test method for Rockwell testing (ASTM E-18-08a) only allows the use of tungsten carbide ball indenters. AMETEK makes a variety of Newage indenters and indenter accessories. We recommend that you contact us , for assistance in specifying and ordering an indenter for your Rockwell , Brinell or Microhardness application.

how to measure brinell hardness

The Brinell hardness test involves pressing a hard ball indenter, usually made of tungsten carbide, into the material’s surface with a specified force. The diameter of the ball is typically 10 mm, but smaller diameters such . We will see Brinell hardness test methods, advantages, disadvantages, and applications. Also its diagram and derivation of brinell hardness number (BHN) . In the standard method of the test, we use a ball indenter of 10mm diameter. Let’s derive the formula of Brinell Hardness Number (BHN) for the Brinell Hardness Test. B.H.N = Load Applied .The Brinell hardness (BH) test measures the hardness of rock (kg/mm2) based on the displacement of a steel ball penetrating into a core sample exposed to a fluid over a certain period. . A wide range of materials can be tested using a Brinell test simply by varying the test load and indenter ball size. In the United States, Brinell testing is .

brinell hardness testing machine

Choose an indenter, typically a hardened steel ball, with a diameter suited for the material and load being used. The standard ball sizes range from 1 mm to 10 mm. . Application of Brinell Hardness Test in Various Industries. The Brinell Hardness Test finds extensive application across diverse industries, playing a crucial role in assessing . An indenter (e.g. ball, cone, pyramid, etc.) is pressed with a certain force into the material surface to be tested. The indentation hardness value is determined from the indentation left behind. . With the Brinell hardness test, a carbide ball is pressed into the material. The indentation surface left behind serves as a measure of the hardness!

The Brinell hardness test method consists of indenting the test material with a 10 mm diameter hardened steel or carbide ball subjected to a load of 3000 kg. For softer materials the load can be reduced to 1500 kg or 500 kg to avoid excessive indentation. The Brinell hardness number (BHN or HBW) describes the hardness of a material. The higher the number, the harder the material. The Brinell hardness test involves pressing a small metal ball into the surface of the test material with a known amount of force. The resulting indentation is then measured and converted into a hardness number.

The typical brinell hardness test uses a 10 millimeters (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29 kN; 6,600 lbf) force. For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball.As per the name, the Brinell hardness test is used to determine the hardness of the given material and this hardness test is in use for many years. As per its definition, a small metal ball acts as the indenter and a force is applied on the ball to produce the given indentation.Brinell Hardness Test Indentation process, load, and duration of load application. Indentation Process: The Brinell hardness test uses a hard steel ball indenter that is pressed into the surface of the material being tested. The diameter of the indentation is measured to determine the hardness of the material.

The Brinell hardness test measures material hardness by determining the diameter of an indentation made by a hardened steel or carbide ball under a specific load. A load, typically ranging from 500 to 3,000 kgf, is applied to the material’s surface for 10-15 seconds, allowing the ball to penetrate and create an indentation.Brinell Hardness Description. The Brinell hardness test uses a ball indenter of diameter, D, which is pressed into the surface of the test piece using a prescribed force, F.The time for the initial application of the force is 2 s to 8 s, and the test force is maintained for 10 s to 15 s.Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. . diameter hardened steel ball as an indenter with a 3,000 kgf (29.42 kN; 6,614 lbf) force. The load is maintained .

Our ball intenders are available in carbide or steel for rockwell hardness testing. Also available as a ball indenter assembly. . Brinell Ball Indenter Select options This product has multiple variants. The options may be chosen on the . Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . Selection Table of Brinell Hardness Test P/D 2. Material type: Brinell hardness number/HB: . 130 for steel ball indenter and 100 for diamond indenter. Table 3-6 Test Specification and Application of Rockwell .The Brinell hardness test is named after its inventor, Johan August Brinell. It involves applying a constant load or force to a spherical indenter made of hardened steel or carbide onto the surface of the material being tested. The indentation diameter is then measured optically. . D is the diameter of the indenter ball in millimetres (mm).

mmd5np pinless lcd moisture meter

For example, it is fairly common when measuring the hardness of an armour casting to use a Brinell hardness test because the indenter is a ball. Remember that the surface of a casting can be fairly irregular and the substrate is likely to be heterogeneous in nature. Likewise, when measuring the micro-hardness of a ceramic, using the correct .

Using ASTM E10 Brinell testing is a method of hardness testing using a tungsten carbide ball as the indenter. The indenter is brought into contact with the planar surface of a test specimen and held with a test force for a specified dwell time. The magnitude of the force and the diameter of the ball can vary depending on the material being .Where HB is the Brinell hardness number, D is the indenter ball’s diameter in millimeters (mm), F is the applied force in kilograms-force (kg), and d is the diameter of the indentation in millimeters (mm). To calculate Brinell hardness using the formula, measure the diameter of the indentation (d) after performing the test and remove the .All information about Brinell hardness testing Test procedure Sample request for the Brinell method Brinell hardness Discover now. . The indenter is a tungsten carbide metal ball, with a diameter of 1, 2.5, 5 or 10 mm, depending upon the specific Brinell method.

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

Choose an indenter, typically a hardened steel ball, with a diameter suited for the material and load being used. The standard ball sizes range from 1 mm to 10 mm. 3. Test Machine Setup. . Advantages and Limitations of the Brinell Hardness Test. The Brinell Hardness Tester, a widely used method for assessing material hardness, offers several .Brinell Hardness Test. Brinell hardness test is one of the indentation hardness tests developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter hardened steel ball as an indenter with a 3,000 kgf (29.42 .

Explore Suntec's wide range of hardness testing indenters. Choose from various options for accurate and consistent material hardness assessments. Trust our high-quality indenters for reliable results. . Brinell Ball Indenter Select options This product has multiple variants. The options may be chosen on the product page

brinell hardness test explained

webbiquíni |147.1M visualizações. Assista aos vídeos mais recentes de #biquíni no TikTok.

ball indenter in brinell hardness test|brinell hardness test explained